Textbook on Hydraulic Cylinders in the SI Units

by Joji Parambath

Click on the image to go to the Amazon.com site

Textbook on Hydraulic Linear Actuators in the English Units

by Joji Parambath

Click on the image to go to the Amazon.com site

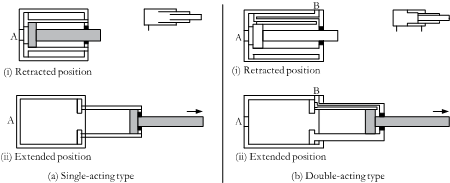

A multi-stage telescopic cylinder has many cylinder bodies inside one another. That is; the piston-rod of the first stage is used as the piston barrel of the second stage, and the second piston-rod is used inside the barrel of the second stage. Similarly, there can be up to six stages in the cylinder. Therefore, the total stroke length of the telescopic cylinder can be up to six times the stroke length of the basic cylinder.

Single-acting Telescopic Cylinder

Figure (a) shows the single-acting telescopic cylinder. It is a multi-stage cylinder with two to six concentric tubular envelopes. Most telescopic cylinders are of the single-acting type, where the fluid pressure always acts in one direction.

Double-acting Telescopic Cylinder

Figure (b) shows the double-acting telescopic cylinder. In this type of telescopic cylinder, the system pressure acts alternately for extending and retracting the cylinder. The double-acting telescopic cylinders are highly complicated and must be specially designed and manufactured to a high degree of precision. Therefore, they are much more expensive than regular hydraulic cylinders.

The telescopic cylinders are ideal for applications that require the use of long-stroke cylinders in a space-constrained environment. They are widely used in hydraulic equipment for the agriculture, construction, and heavy engineering industry. They are commonly used in the mobile hydraulic systems for the tilting of truck dump bodies and forklifts, the lifting in hydraulic cranes, and material handling. The telescopic cylinders are constructed of single-acting and double-acting varieties.

Joji Parambath

Director

Fluidsys Training Centre Pvt Ltd

Bangalore, India